Sustainability thought through

A heating oil-free holiday resort – how the idea of a district heating plant in Obereggen protects nature and saves money at the same time

“Actually it's the same here as with the heating at home,” says Michael Kalser. “If we maintain it regularly, then it keeps running without any problems.” However, the scale of the system that he has to do this with in Obereggen differs quite considerably from the boiler in a private household. Here in the district heating plant, which nestles idyllically against the majestic backdrop of the Latemar massif, Michael and his team work hard to ensure that each year around four million kilowatt hours of heat are produced using waste wood from the Eggental Valley. In the past, around half a million litres of heating oil were used to do this. Today, in contrast, Obereggen is practically heating oil-free – and the people responsible in the Eggental Valley can reflect on this situation with satisfaction.

When the 2100 kilowatt biomass boiler for winter operation is still running at full power, Michael gets to work on preparing the considerably smaller boiler, which has an output of 850 kilowatts, for the summer season. “Of course it takes time to maintain the systems,” he says. Deposits have to be removed, the sliding floor has to be attended to or the flue pipes cleaned – all to ensure that the heating plant runs smoothly again. And when the large boiler has its break in summer, Michael has enough time to get it ready for the winter again. “We have never yet had any problems worth mentioning,” says Michael about his experiences with the boilers, which consume around 5000 loose cubic metres of organic wood chips per year from the Eggental’s sawmills.

“Firstly it’s the short transport distances,” says Michael, that make the idea of the Obereggen district heating plant truly sustainable. There are only six kilometres between the sawmills and the district heating plant. “It could hardly be less,” he says. When the wood chips are delivered, Michael usually doesn’t even know about it. The energy supplier ensures independently that the storage facilities are sufficiently full to allow the boiler to operate for four to five days at a time. In any case, Michael spends only a little of his working time actually at the district heating plant – unless he is in the process of maintaining one of the boilers. “The system is fully automatic,” he explains. If he has to intervene, then usually it is by remote diagnosis and control by smartphone.

„The project was almost a no-brainer“

“The project was almost a no-brainer,” says Erich Thaler, hotelier at the Hotel Cristal in Obereggen and one of the instigators of the project, looking back. From the initial idea to the start of energy production in the district heating plant in 2007 took less than two years. According to Thaler, as a location with a strong emphasis on tourism, on the one hand, Obereggen presents the ideal conditions with its compact structure and short distances. And on the other hand, it was not difficult to convince the hotel operators of a concept that not only promised sustainability but was also financially attractive.

And the fact that the energy price from the district heating plant would even occasionally be as much as 40 per cent below the heating oil price was something that nobody could have anticipated for sure. But the prospect for cheaper energy and a value added chain that stays in the Eggental Valley led to 10 hotel businesses and the lift company coming together to form a cooperative. And there are still plenty of satisfied faces among the eleven equal participants today. In total, Erich Thaler calculates that the savings so far amount to two million euros, which corresponds on average to 25000 tonnes less CO2 per company.

Every day since the Obereggen district heating plant started producing heat has therefore been a good day – both for the environment and for the budget of the cooperative. For Michael Kalser and his team, that is a good feeling, even though day-to-day they tend to focus more on ensuring that everything runs smoothly – until eventually there is only fine, powdery grey ash in the container on the outside of the heating plant. This is the end product of a highly-efficient and environmentally-friendly combustion process. “Relatively little,” says Michael, remains of the giant mountains of wood chips that pile up in front of the district heating plant.

The wood chips first move automatically by sliding floor into the primary combustion chamber, where the burning begins with the admixture of air. The flue gas produced in the process is fed via ventilators into the secondary combustion chamber for a second combustion process before the heat is transferred to the water circuit via flue pipes. Afterwards, the flue gas still has a temperature of up to 200 degrees,” explains Michael. That's too hot to vent it directly to the atmosphere, which is why a condensation unit ensures that the residual heat is used to best possible effect.

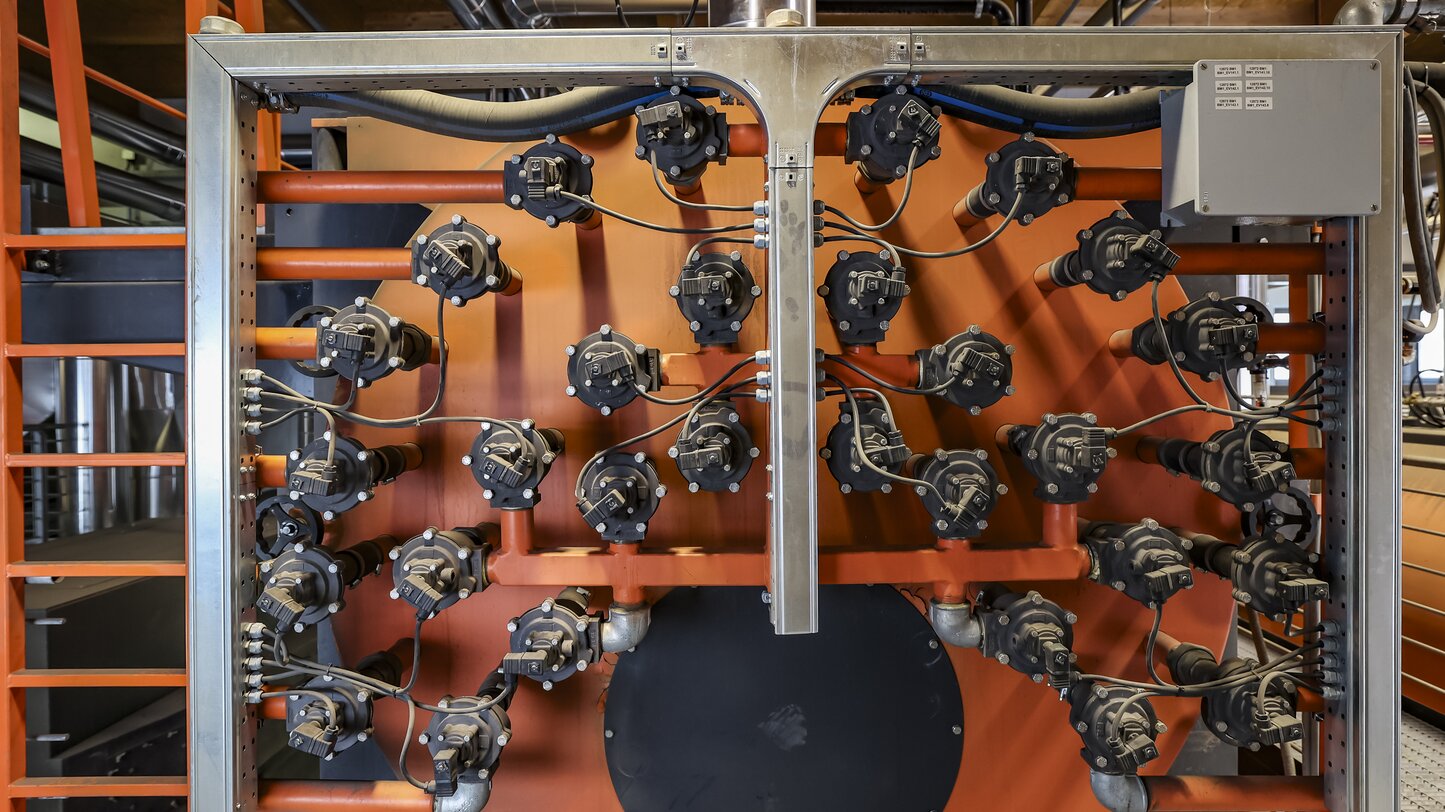

The heat is transferred via plate heat exchangers into a closed circuit and ultimately to the heating systems of the eleven consumers that are connected to the Obereggen district heating network. At a pressure of around seven bar, the water circulates in the 1.8 kilometre-long district heating circuit, which is fed from an impressive 20,000 litre hot water tank with water at 90º C.

„If we think sustainability through properly“

“We have ensured redundancy for everything that is essential for the system’s smooth running.” This means that in the event that one of the network or boiler pumps fails, there are always replacement devices ready to spring into action. If there is a power failure, the emergency power generator can always ensure that the district heating plant continues to operate. And if there were to be an interruption to the burning of wood, the oil boiler that has been installed for emergencies ensures that nobody will freeze in Obereggen or have to take a cold shower. It has little negative impact on the overall environmental balance of the district heating plant if the oil boiler has very occasionally to be powered up briefly. “On average, we do not need the oil boiler for any longer than one hour per month,” explains Michael.

Either way, the fact that the exhaust gases are filtered before they leave the district heating plant, is not only a statutory requirement today, but is also, of course, part of the concept of sustainability of the district heating plant in Obereggen. A multi-cyclone filter, a fine particulate filter and an electro-filter ensure that statutory limits for emissions and particulate matter come nowhere near being exceeded.

“If we think sustainability through properly,” says Erich Thaler, “then the district heating plant in Obereggen is an important part of it.” And that is so, even though the idea of making Obereggen practically heating oil-free, was not an ideological choice, but rather dictated by pragmatism. “If everyone benefits,” he says, “then our nature will benefit too.” In future, it may be that it will also be possible to produce electricity in this way in Obereggen District Heating Plant. Indeed, the photovoltaic plant that was modernised in autumn 2024 is already producing more and more energy in the sunny Eggental Valley. Theoretically, however, the district heating plant could itself work as a generator of electricity, if both power and heat were to be produced on the co-generation principle. However, at present that is still uneconomical since there are extreme fluctuations in demand between winter and summer, between high season and the weeks when the hotels close. But, if there are further advances in electricity storage technology, “then naturally we would feel a dual effect,” explains Thaler. However, the fact that a new power plant would need to be built to achieve this is no cause for concern for Thaler. First and foremost because he knows that it would be worthwhile economically. And secondly, because he says, “If we want to work cost-effectively in the long term, then it will also be necessary to invest.”