Carved from the best wood

An unbelievable 70% of the Eggental is covered by forest - so it is obvious that the forestry and timber industry has always been THE most important sector of the economy here. Between economic activity and traditional handicraft, the wood from the valley provides one thing above all else: great stories.

A look back: the Eggental goes to Venice!

As long ago as the 16th century, many Eggental natives, and in particular those from Deutschnofen, were able to make a living by exporting the timber from larch, Scots pine, spruce and fir trees. The transport route passed via Deutschnofen and the Branten Valley to Laives and then on to Bronzolo, where the timber was floated down the river Etsch/Adige until it reached Venice. The viscous resin known as “loerget” was used in Venice for shipbuilding. And reputedly, the pillars in St Mark’s Square, upon which two lions stand, come from the forests of Deutschnofen.

The main consumers of wood from the Eggental were citizens of Bolzano, residents of the Upper Etsch valley and Bolzano winegrowers as well as the sparsely wooded Italy. Italian timber traders also sold the wood further afield, to Algeria, England, Greece and Egypt.

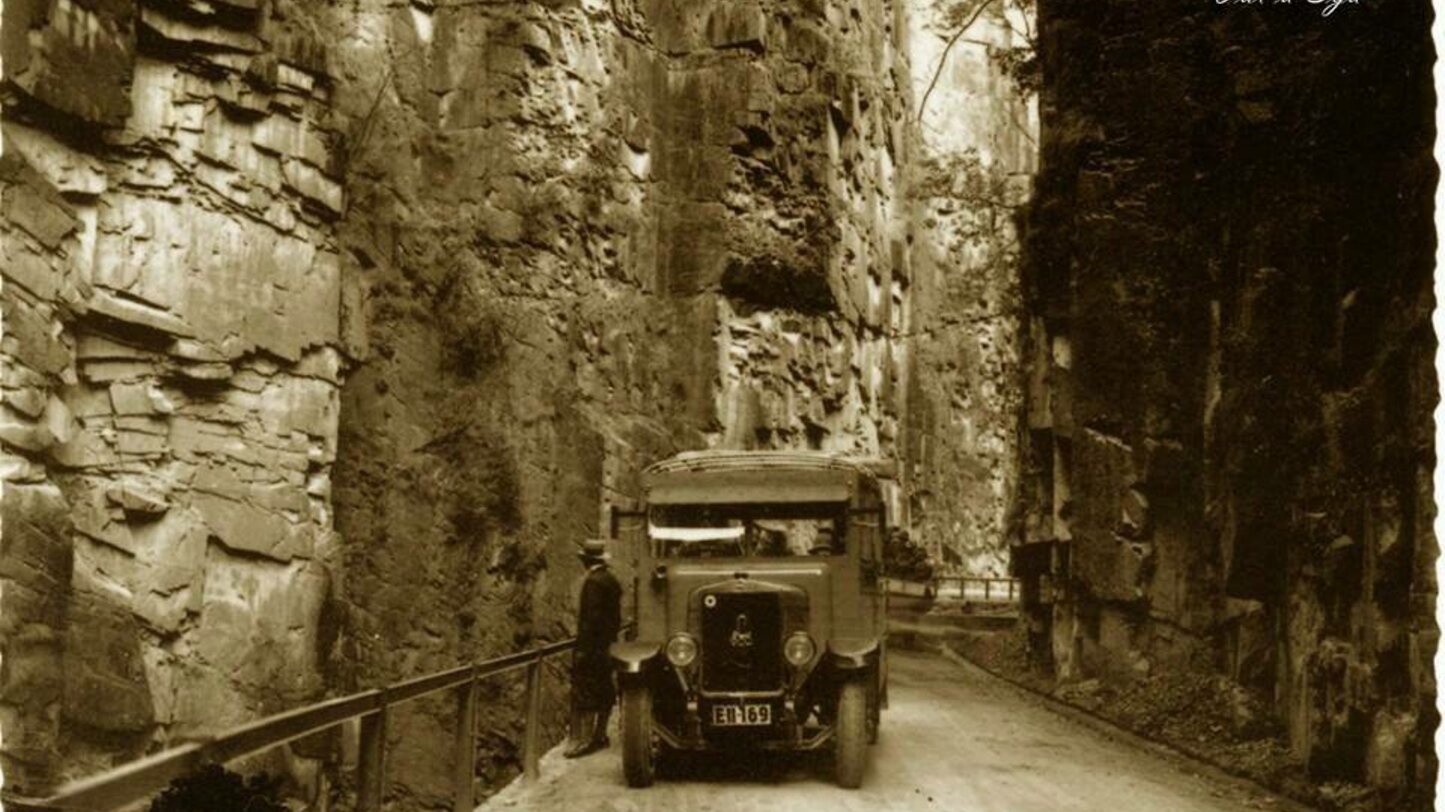

The increase in road building at the end of the 19th century not only ensured greater tourist numbers, but also new transport routes, along which the products of the Eggental could move from one place to another. An alternative to these routes was the “drift”, in other words, transport by river. The Eggental beck was – especially at high water as the snow melted in spring - suitable for the transport of wood and the drift to Kardaun, even if the steep terrain made the endeavour more difficult.

Where traditions persist

The Venetian saw

It isn’t just the old farmsteads and agricultural traditions that give one the feeling that time passes more slowly in some parts of the Eggental than elsewhere. A special sawing technique, that combines two important elements of the valley - timber and the power of water - with one another, stretches back for centuries. We are talking about the “Venetian saw”, which can be traced back to sketches by Leonardo da Vinci that envisaged a waterwheel, a saw blade moving horizontally and a timber bench on rollers. The cart loaded with the trunk to be cut rolls over an inclined plane to the saw blade, which is driven by hydropower. The Venetians took over this revolutionary technology from da Vinci but could not use it themselves. For this reason, they passed it on to the farmers from whom they purchased their wood - and in this way the Eggental natives adopted the technique. From what was once 73 saws in the valley, there are now only two still in operation: the Tischler saw of Josef Mairhofer in Welschnofen and the Flecker saw of Alfred Sinner in Eggen.

The Latemar forest and tonewood

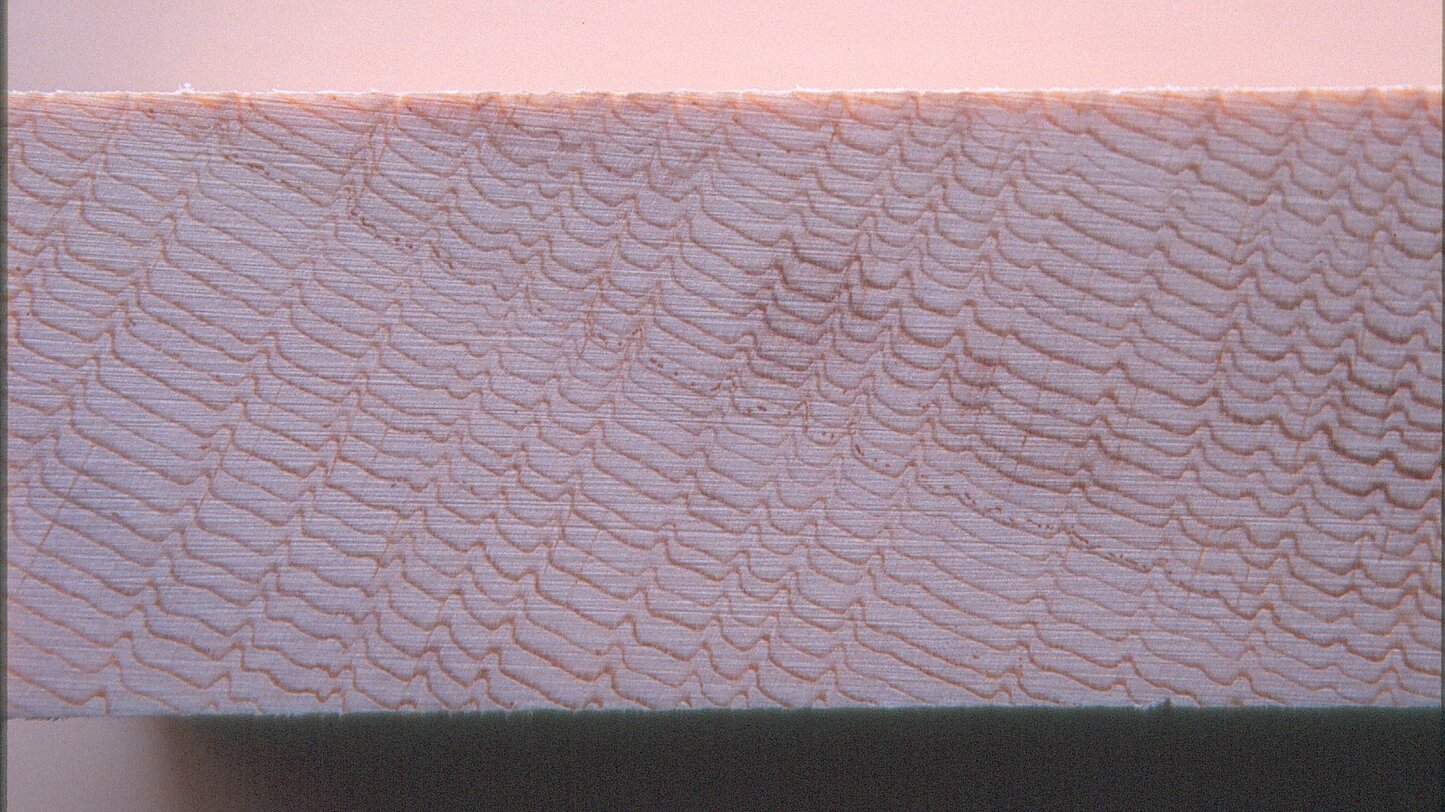

At an altitude of 1400 to 1800 metres, directly below the craggy, pale slopes of the northern side of the Latemar, lies the Latemar forest. The location and calciferous soils, the temperatures and the climatic conditions are ideal for growing spruces, which reach between 48 and 51 metres tall here. The trees are felled from September - except for the Hazel Spruce, which supplies valuable tonewood for making musical instruments: the body of violins, cellos and guitars as well as harps, pianos, didgeridoos and alpenhorns. These trees are not felled until between November and January, during the sap dormancy period. The spruce trees used for tonewood are distinguished by their low specific gravity, which is responsible for the speed at which the sound travels, and by narrow, undulating growth rings, which are important for the resonance. Apart from this, they have no flaws in the wood or knotholes. The centre section of the trees is used for making musical instruments, which will ideally have a circumference of 4-5 metres, making these trees 250 to 300 years old!

The spruces from the Latemar forest are only processed in the Latemar saw mill in Welschnofen by trained lumberjacks – the felling work itself is only carried out in pairs or groups of three, whilst the saw may only be operated by one worker. The majority of the processed wood goes to northern Italy, with a small proportion going to Germany, Austria and Switzerland. Every trunk bears the “Latemar” seal of quality.

Wood: then, as today, THE raw material in Eggental

Even today, wood as a raw material is extremely important in Eggental. Several large timber trading companies are based here. For 15 years, the biomass has been used intensively as a renewable resource. Two district heating plants in Obereggen and Welschnofen supply over 500 households and businesses with heat. This allows around 1.2 million litres of heating oil to be saved every year. Sixteen accommodation providers in the Eggental and the office buildings of Obereggen Latemar AG are also connected to the district heating plant. The wood chip plants and both district heating plants are fed with biomass from the Eggental.